BUGATTI PICCHI TRANSFER TR 10 – 15/OS MACHINING CENTRE

A COMMERCIAL OFFER FOR SALE OF

BUGATTI PICCHI TRANSFER TR 10 – 15/OS MACHINING CENTRE

Price EUR 265 000 EUR net

The PICCHI multi-spindle automatic machining centre is designed for serial production of parts made of semi-finished products mounted in further handles of the automatic machine. The automatic machine has 15 heads, including 6 on the right, 4 on the left and 5 on the table rotation axis, of which there are 12 drilling and milling heads and 3 thread heads. The workbench is equipped with 10 holders, in which the semi-finished products are sequentially mounted and, by turning the table (turning vertically downwards), subsequent machining operations are performed (such as milling, threading, drilling). It is possible to perform 15 operations on 9 elements at the same time. The automatic machine is used for machining of forgings and brass blocks. It was used for production of, among others, bodies of safety valves, water meters, multi-valves, bodies of solenoid valves, pneumatic components and power hydraulics.

The example of products after machining on the automatic machine:

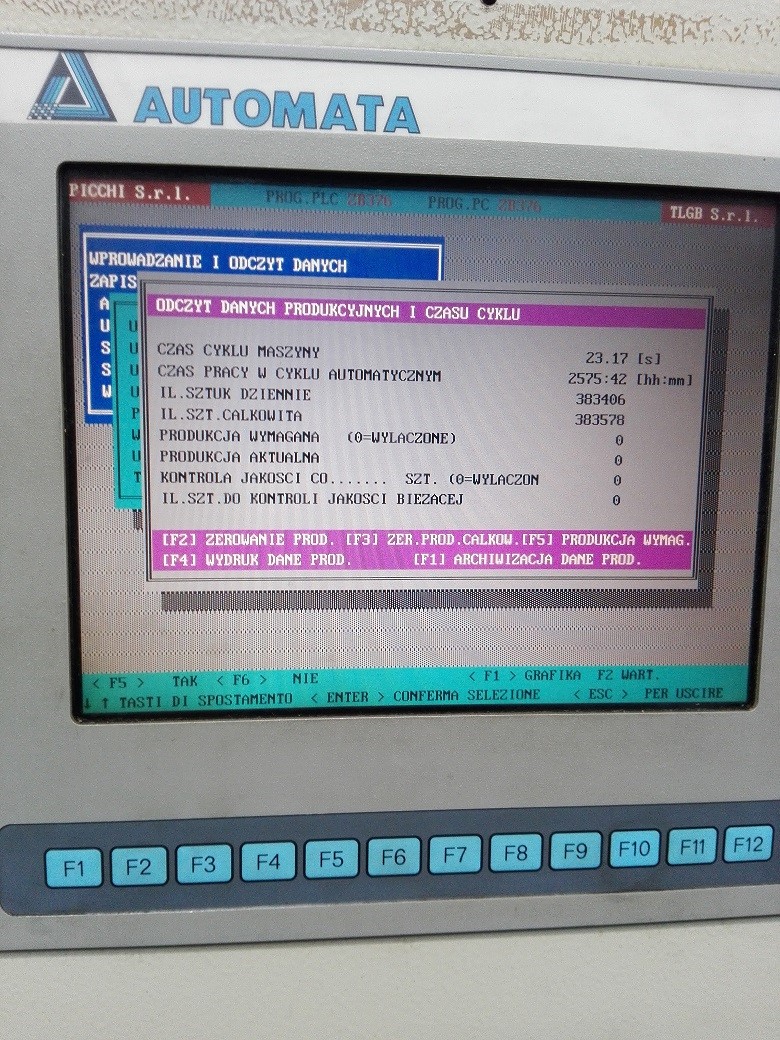

Capacity: 285 pieces per hour of the above-indicate product - input and output status.

Unit time: 0.21 minute/1 piece..

Capacity: 125 pieces per hour of the above-indicate product - after machining in one fastening of a raw forging.

Unit time: 0.48 minute/1 piece.

GENERAL DATA

Year of production 1998

Dimensions [mm] Machine: 3800 x 4300

Control cabinet with a refrigerating unit: 3500 x 900

The entire surface: 5700 x 5000

Total power 85 kW

Weight 9,2 t

Supply voltage 400 V

Frequency 50 Hz

A LARGE FORMAT TURNTABLE

Rotation axis horizontal

Maximum dimension of a workpiece 525 mm

Number of fixings 10

Lock system Toothed rings: Hirth Ø 450

Torque reducer Cyclo FC-A45G-89

Motor brushless with a nominal torque of 18 Nm, type Simens IFT5076 3000 rotations per minute

Reducer connection direct

Rotation direction downwards

A VISE

Opening stroke of a vise 0-26 mm

Maximum force of a locking vice (4 MPa) 1176 daN

A DRILL AND MILLING UNIT (12 PIECES)

Spindle diameter 100 mm (ISO 40 mounting)

Maximum speed in the Z axis 12 m/minute

Speed range of a spindle 1000-2000 revs/minute 1440-2880 revs/minute

A CONTROL CABINET: SINUMERIK software

ADDITIONAL EQUIPMENT (included in the price of the machine):

A hydraulic unit: Berarma type 02PSP3-80

A lubrication unit: Viovoil type KVOP/0.98

A chip conveyor

Material of chips: brass

Maximum size of chips: 30 mm

A filtering system: vibrating filtering

A pump: SACEMI 3.6 kW type AP 30B/200

The prices provided do not include: the cost of disassembly/assembly, loading, transport

Payment: 100% prepayment before disassembly

Validity of the offer: until the machine is sold

Telephone: +48 608-088-001

E-mail: p.dytkowski@fach.pl

Skype: p.dytkowski

In case of any questions or doubts regarding the offer, please do not hesitate to contact us by phone or email.

Yours faithfully

Piotr Dytkowski

Prezes Zarządu / Dyrektor Generalny „FACH” S.A.